Genvik stainless steel submersible pumps are multistage single suction centrifugal type, provided with integral check-valve and NEMA standard coupling. These pumps are available with fabricated impellers and diffusers made of SS 304/316 and the shaft is made of SS 304/431. The integral check valve prevents back flow and reduces the risk of water hammer which paves the way for trouble free performance. The screen is designed with utmost care so as not to reduce the inflow of water and at the same time to prevent damage to the pump and clogging due to the entry of sand and other foreign particles.

Application

Pump Operation

| Nominal Diameter |

8” |

| Power Range in kW |

5.5kW-130kW |

| Speed |

2900 rpm |

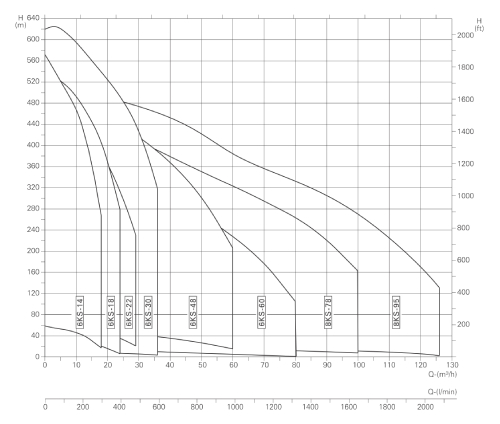

| Flow Range (m³/hr) |

20 - 126 |

| Max. Recommended Head (m) |

8 - 476 |

| Delivery size in mm |

100 & 125 |

| Max. Operating Pressure |

5.2 Mpa (52 bar) |

| Horizontal Installation |

Min. 30° angle |

Material of Construction

| MOC |

8” |

| Impeller |

AISI 304 / 316 |

| Diffuser |

AISI 304 / 316 |

| Valve Housing |

AISI 304 / 316 |

| Valve |

AISI 304 / 316 |

| Cable Guard |

AISI 304 / 316 |

| Coupling |

AISI 329 |

| Suction Interconnector |

AISI 304 / 316 |

| pH |

6.5 to 8.5 |

| Turbidity |

50 ppm silica scale (max.) |

| Viscosity |

6 1.75x10 m²/sec (max.) |

| Hardness (Drinking Water) |

300 (max.) |

| Specific gravity |

1.004 (max.) |

| Allowable solids |

3000 ppm (max.) |

| Chlorine ion density |

500 ppm (max.) |

| Permissible amount of sand |

50 g/m³ (max.) |

| Temperature |

33°C (max.) NBR, 90°C VITON |